Designing a shoe is a combination of craftsmanship and advanced digital processes. We can walk together along this adventurous journey

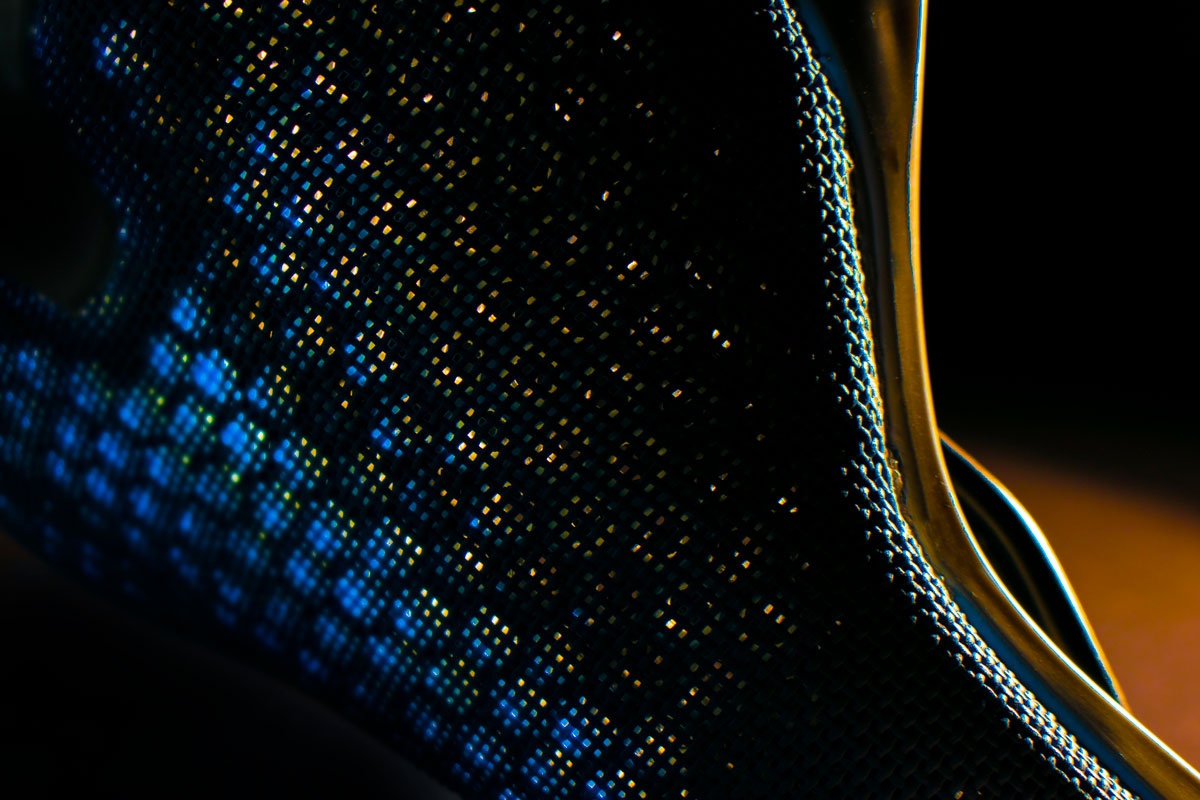

Concept

The first step in the shoemaking process is to put on paper a vision for your footwear product. Our expert designers will create detailed concepts so that you can envision your product, steer its creation and get a clear picture of where we want to go. To each step of the concept and design phase, reviews are performed so that the idea of the shoe becomes more and more clear as the time goes on. This step of the process is the most creative, where everything can be considered, even the most outrageous and disruptive idea. The construction of the next great model comes from the distruction of the past preconceived notions.

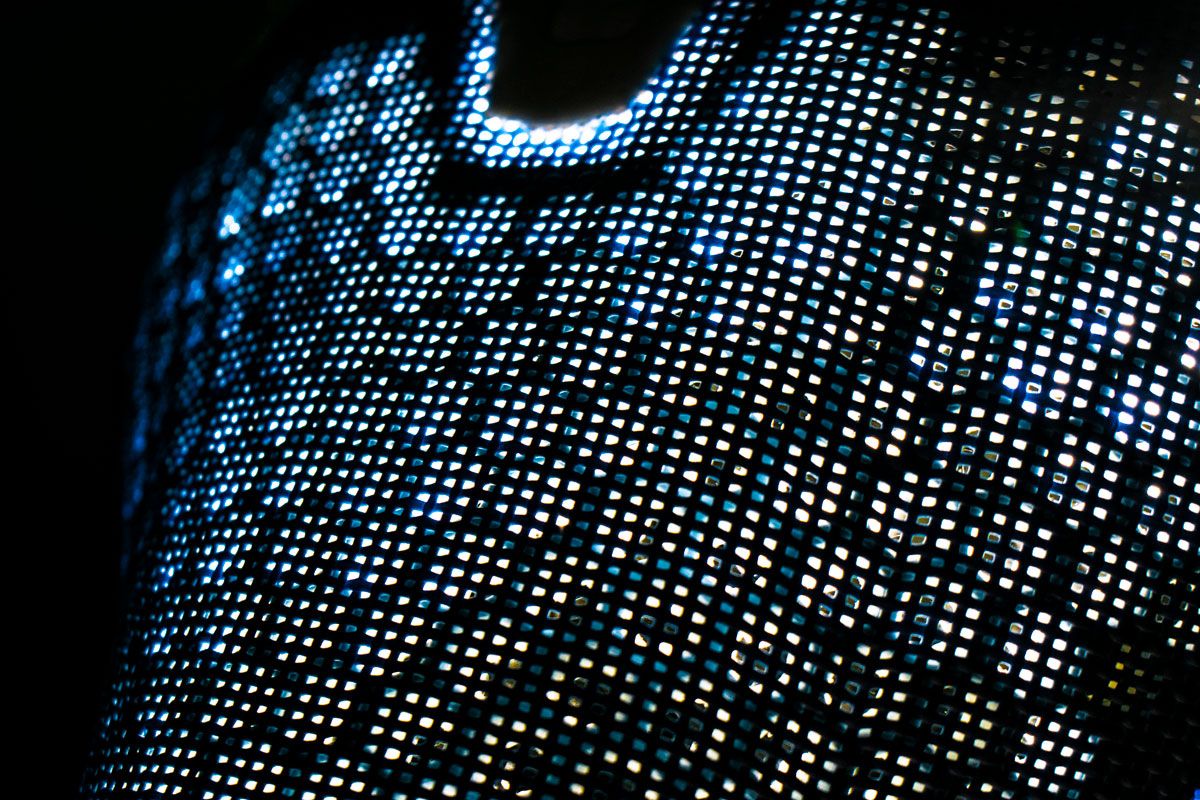

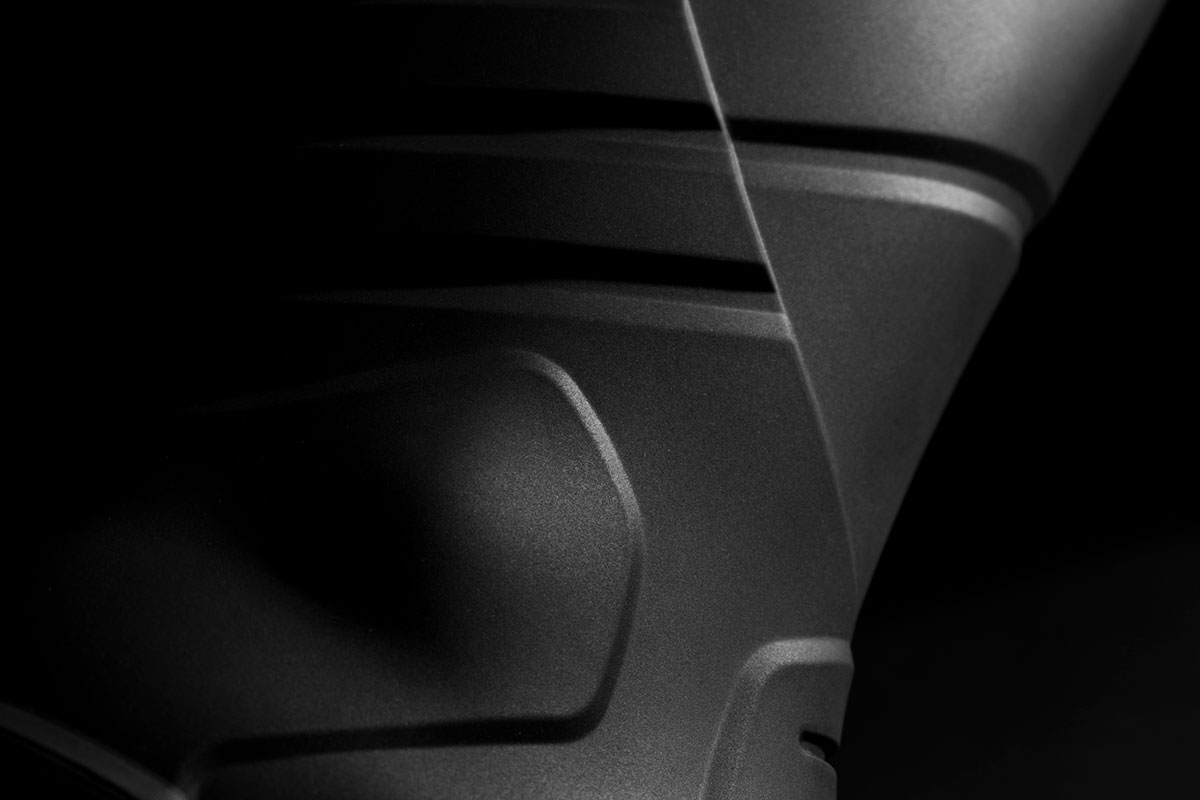

Development

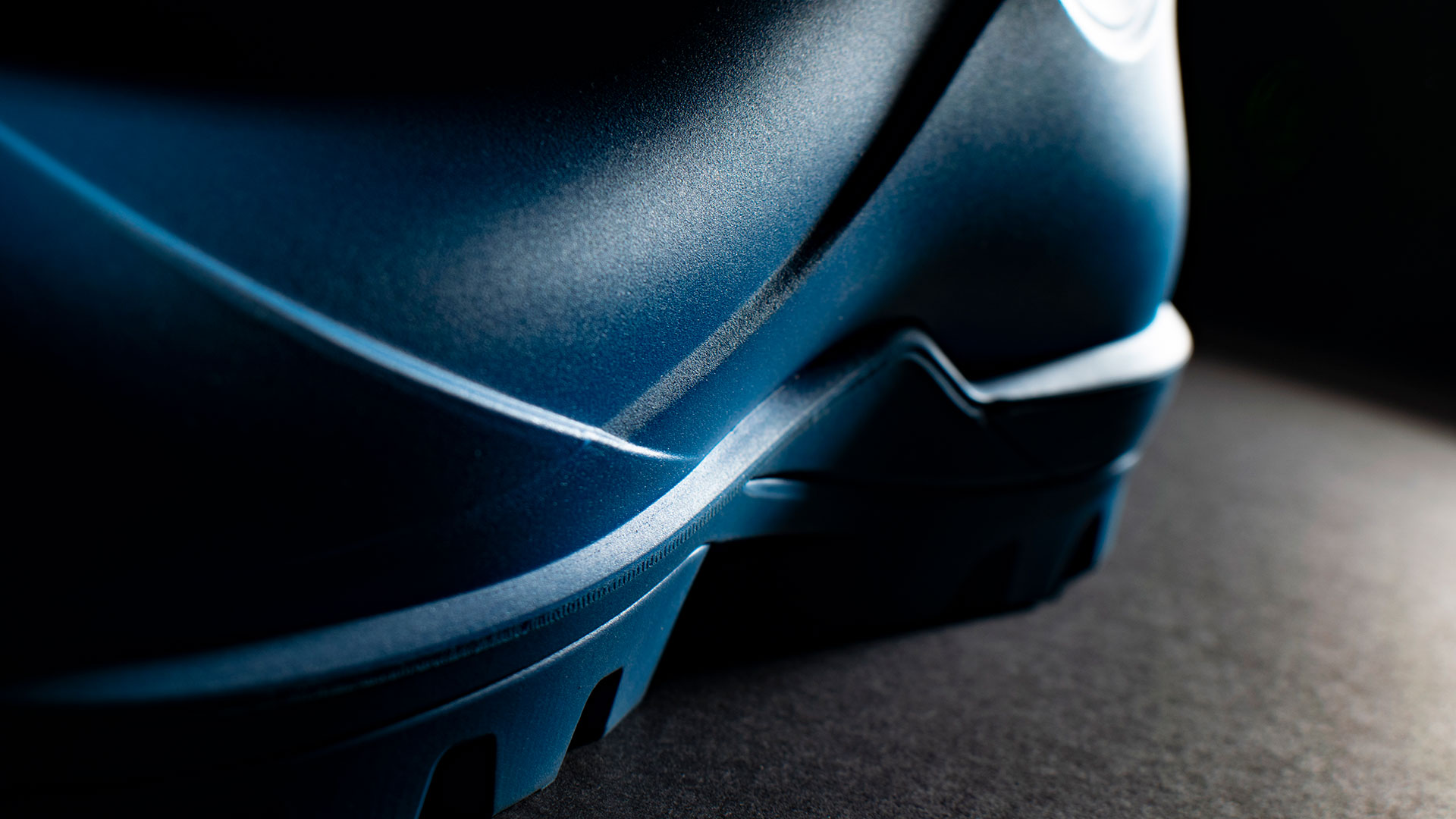

Developing the shoe brings the idea into engineering. Our engineering department can provide both the upper model, with all the patterns needed to stitch the footwear, and the sole and other moulded parts. We are pioneer of 3D technologies since the early 1990s we have invested in CAD tools, 3D scanners, milling machines and 3D printers. We can deliver the full prototype without involving any third party. If your development needs a secretive route, we can provide that, reducing the leak potential by doing the full process in-house.

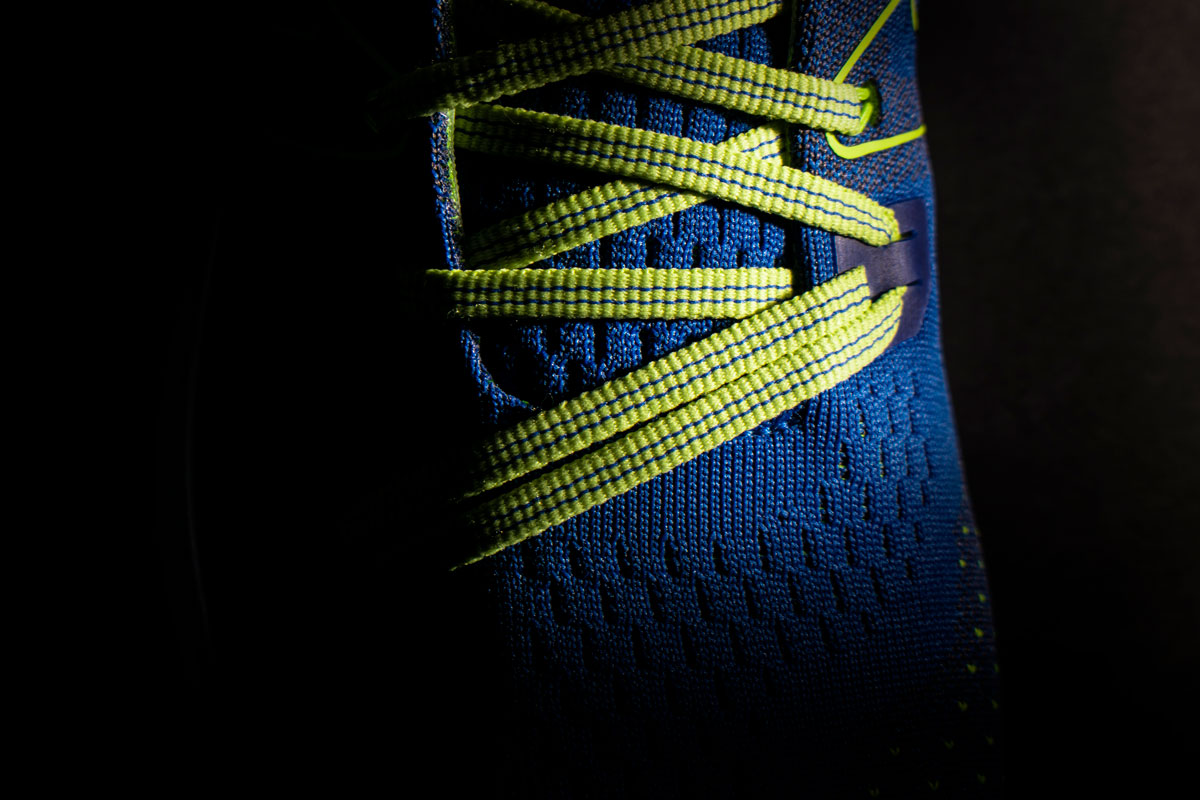

Production

Once the shoe is ready and you are satisfied with how it looks and tests we move into production mode. If you want to produce in Italy we have the capability of doing that, if you want to outsource to Asia or East Europe we have the right global connections to reach the target you want to reach. It all depends on your budget, time allocation and price you want to sell. If you need anything special we work quickly and efficiently so that your demands are met.